Products

hallmark

- Contaminants and defects at the nanometer scale can be evaluated transparently.

- Single shot instantaneous depth information

- High-speed measurement without focusing

- Non-destructive, non-contact and non-invasive measurements

- High-speed scanning of any surface for easy determination of the measurement position

norm

| Resolution x, y | 691 nm (single), 488 nm (component) | |||

| Field of view x, y | 700 x 700 microns | |||

| Resolution z | 10 nm (delayed) | |||

| Digital refocusing range z | ± 700 microns | |||

| sample size | 100×80×t20 mm | |||

| (when connected to a multifunctional sample holder) | ||||

| sample stage | Automatic XY Carrier Stage for Fine Tuning | |||

| X: ±10 mm Y: ±10 mm | ||||

| Carrier table for coarse adjustment | ||||

| X: 129 mm Y: 85 mm | ||||

| lasers | Wavelength 638 nm | |||

| Output 0.39 mW or less, Class1 | ||||

| (intensity of irradiation of the sample) | ||||

| descriptive | Main body: 505 (W) x 630 (D) x 439 (H) | |||

| (Width x Depth x Height) mm | ||||

| weights | 41 kg | |||

| power wastage | Mainframe: 290 VA | |||

| *Excludes PCs and accessories. | ||||

appliance

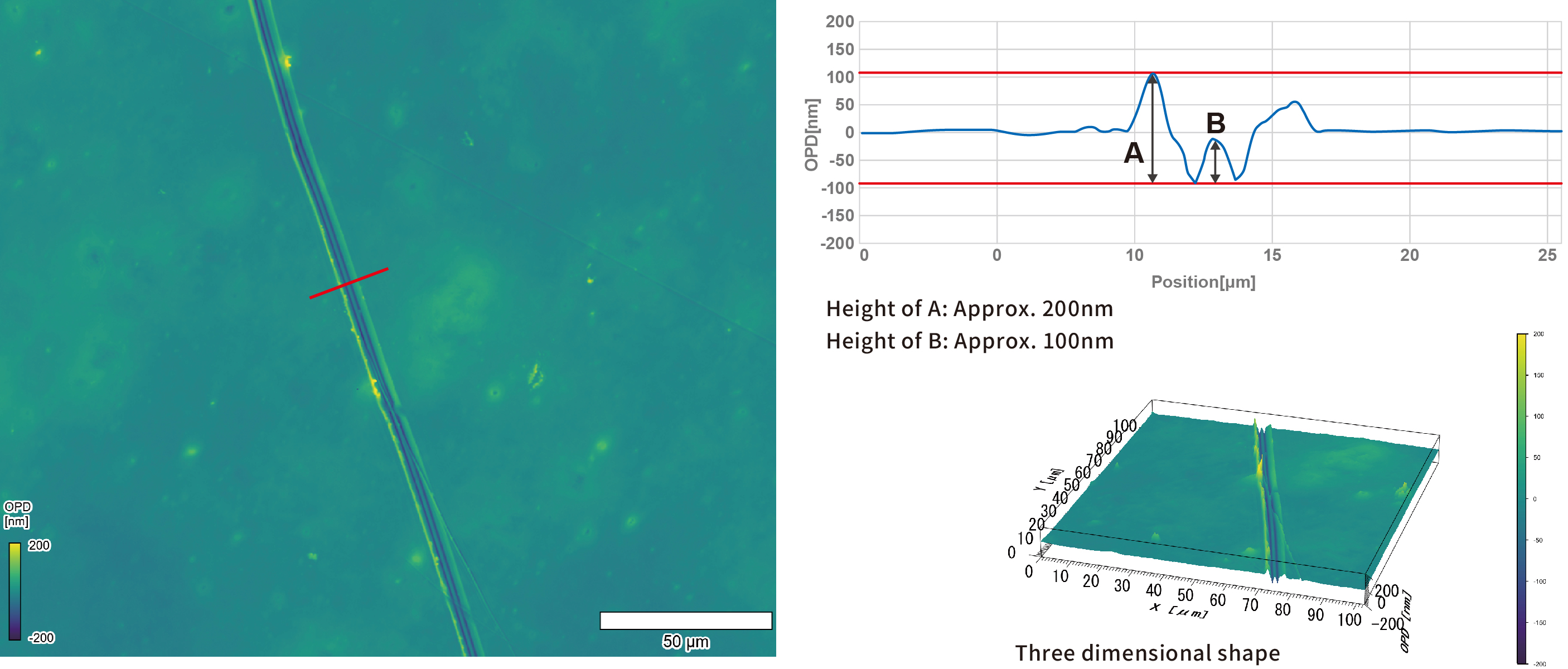

Nano-order shape information can be obtained in a non-contact, non-destructive and non-invasive manner. Acquiring depth-direction information from a single shot allows visualization and quantification of the cross-sectional shape of scratches as well as defects invisible to the naked eye on the surface of transparent films.

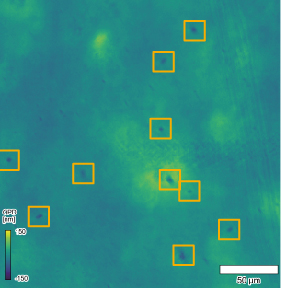

The filler inside the transparent film can be observed in a single shot, which is invisible to the naked eye. In addition, by changing the focus in the direction of depth after measurement, the filler at each depth can be recognized.