Product Model

| model number | spectral range | Maximum measured power1 | Minimum measured power2 |

| 918D-IG-OD1R Optical Power Detector, Indium Gallium Arsenide, 800-1650 nm, OD1 Attenuator | 800 - 1650 nm | 100 mW | 20 pW |

| 918D-IG-OD2R Optical Power Detector, Indium Gallium Arsenide, 800-1650 nm, OD2 Attenuator | 800 - 1650 nm | 1000 mW | 20 pW |

| 918D-IG-OD3R Optical Power Detector, Indium Gallium Arsenide, 800-1650 nm, OD3 Attenuator | 800 - 1650 nm | 2000 mW | 20 pW |

| 918D-IR-OD1R Optical Power Detector, InGaAs, 800-1650 nm, OD1 Attenuator | 780 - 1800 nm | 100 mW | 5 nW |

| 918D-IR-OD2R Optical Power Detector, Germanium, 780-1800 nm, OD2 Attenuator | 780 - 1800 nm | 1000 mW | 5 nW |

| 918D-IR-OD3R Optical Power Detector, Germanium, 780-1800 nm, OD3 Attenuator | 780 - 1800 nm | 2000 mW | 5 nW |

| 918D-SL-OD1R Optical Power Detector, Silicon, 400-1100 nm, OD1 Attenuator | 400 - 1100 nm | 40 mW | 20 pW |

| 918D-SL-OD2R Optical Power Detector, Silicon, 400-1100 nm, OD2 Attenuator | 400 - 1100 nm | 400 mW | 20 pW |

| 918D-SL-OD3R Optical Power Detector, Silicon, 400-1100 nm, OD3 Attenuator | 400 - 1100 nm | 2000 mW | 20 pW |

| 918D-UV-OD3R UV Silicon Detector, 200-1100 nm, OD3 Attenuator | 200 - 1100 nm | 200 mW | 20 pW |

Notes.

- When used with the 1830-R, 1918-R, 1936-R, or 2936-R benchtop optical power meter.

- When used with the 1936-R or 2936-R benchtop optical power meter.

hallmark

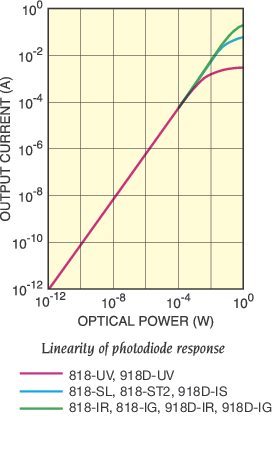

Excellent photodiode linearity

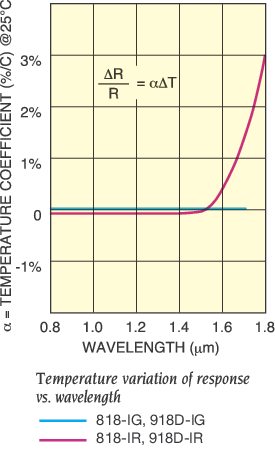

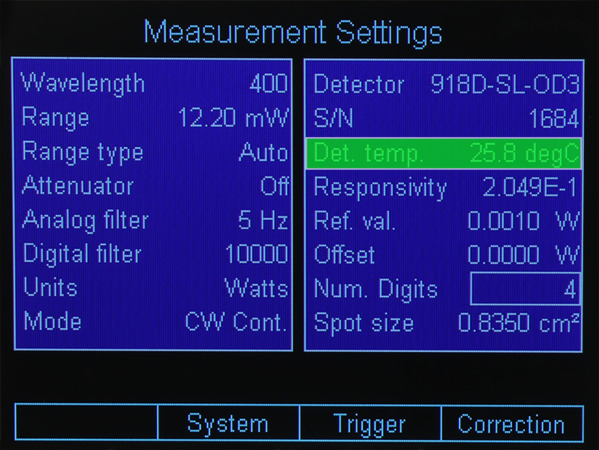

Variation of response speed with temperature

A natural characteristic of photodiodes is that their optical response varies with the temperature near the bandgap of the semiconductor material.Newport's 918D series sensors have a thermocouple near the photodiode, which allows specific Newport meters to read the temperature and automatically adjust the response to ensure the most accurate measurements.

Factors affecting maximum measurable power

The maximum measurable power of a photodiode sensor depends on a variety of factors such as the wavelength of the incident light, the saturation of the photodiode's current output, the temperature, the use of an attenuator, and the maximum current input value of the power meter. Newport offers maximum power specifications based on the model of the power meter, with or without an attenuator, as well as the maximum power level with respect to wavelength. With these factors affecting measurable power, it is critical to select the right detector for your application.

enhancement

The 918D series photodiode probes are designed to outperform Newport's industry-proven 818 series calibrated photodiode probes by enhancing their performance with advanced features. They feature integrated calibration data memory, built-in OD1, OD2, or OD3 attenuators with electronic attenuator on/off sensors, and sensing electronics for temperature drift compensation, which allows the probe to measure more accurately during temperature changes.

Wide dynamic range (with built-in attenuator)

The unique OD3 attenuation technology extends the calibrated optical dynamic range of our detectors by three orders of magnitude. Our attenuator design provides high damage thresholds and spectral flatness. This wider dynamic range is achieved through the low NEP associated with the photodiodes being used by Newport. For input powers less than 1 mW, we recommend placing the attenuator in the OFF position (0.1 mW for the 918D-UV-OD3R between 200 - 400 nm) to maximize the signal-to-noise ratio. The attenuator has an aperture of 10.3 mm.

Tightest calibration uncertainty

The 918D series includes a full spectral response calibration using NIST-traceable standards, accomplished with high-precision equipment maintained at the Newport Optical Probe Calibration Facility. Rigorous calibration equipment and process controls allow for the tightest calibration uncertainties in the industry. Each probe comes with calibration data stored electronically in the probe's EEPROM. Each probe is accompanied by a calibration certificate and actual calibration curves and data in attenuator mode and no attenuator mode. To maintain accuracy and ensure performance, Newport recommends that photodiode probes be calibrated annually.

Internal temperature sensor

An internal temperature sensor on the probe head is used to compensate for responsivity drift caused by changes in photodiode temperature. The responsivity change is most sensitive near the bandgap, and the power meter calculates the temperature and automatically updates the responsivity value so that measurements remain accurate.Models 1936-R, 2936-R, 1919-R, and 841-PE-USB power meters are enabled for this feature.

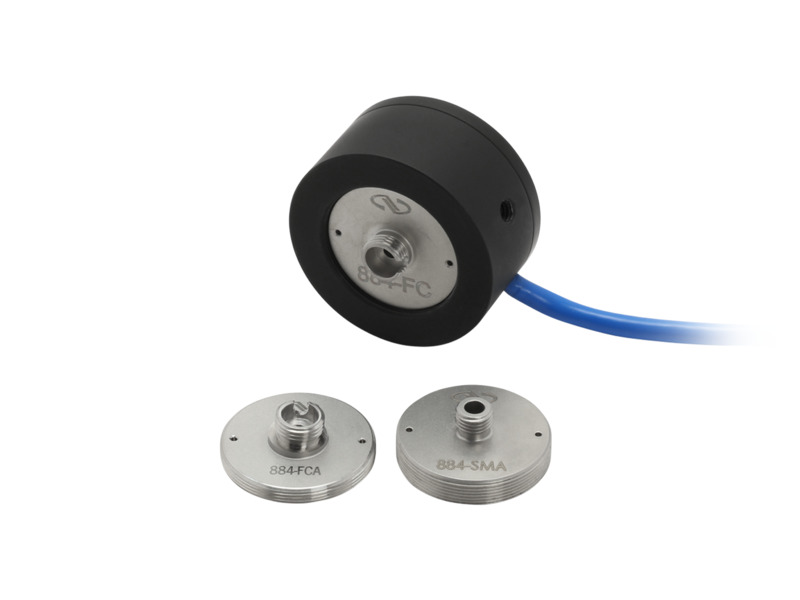

Fiber Optic Application Adapters

These photodiode sensors can be converted to measure the optical power of a connected fiber or a bare fiber.Newport offers a comprehensive line of screw-in fiber optic adapters to match a wide range of connector types. Our bare fiber holders and adapter holders are designed to hold 250-µm bare fiber without damaging the fiber.

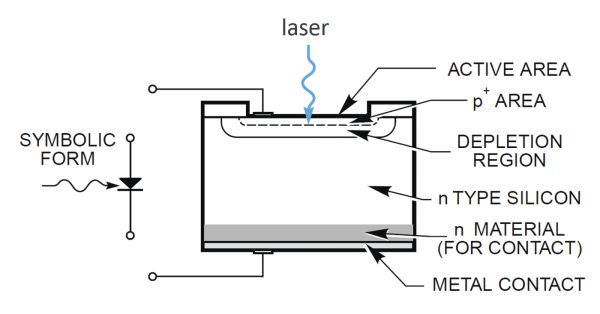

Photodiode Sensor Physics

A photodiode consists of a semiconductor p-n junction similar to laser diodes and LEDs. However, the basic radiation process involved is absorption. Photons falling on the p-n junction lead to the formation of electron-hole pairs. In photovoltaic mode, the electron-hole pairs migrate to both sides of the p-n junction, resulting in a voltage. A key difference between semiconductor photon sources and photon detectors is that the former requires the use of direct bandgap semiconductors, while the latter can use indirect bandgap semiconductors. Since conservation of energy and momentum need to be satisfied simultaneously, the possibility of photon emission in indirect bandgap semiconductors is greatly reduced, but this is not the case for absorption. An easily realizable two-step process will be achieved when electrons are excited to a high level in the conduction band and subsequently their momentum is transferred to phonons during relaxation. Since this process can be continuous, it is more likely to occur than an emission process in which both steps must occur simultaneously.